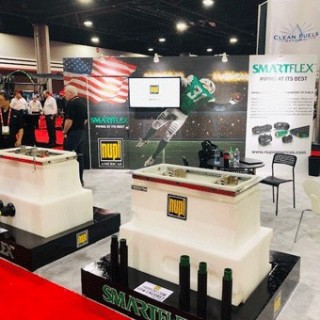

NEW SMARTFLEX PRODUCTS ON SHOW AT PEI

The SMARTFLEX complete multilayer piping system for the transfer of automotive fuels and dangerous fluids was successfully showcased at PEI NACS SHOW 2019 in Atlanta during the event of the year for the fuel and fluid handling equipment and services industry. The highlight of 2019 edition were our new manhole cover, double wall tank sumps and entry boots.

The new watertight raintight anti-slip manhole cover class C250 – D400 manufactured in Italy is ideally suited for petrol station forecourts, roadways as well as pedestrian and industrial areas. It is made of a material with a very low friction coefficient and is designed for use in both wet and dry conditions. The use of the lifting tool reduces the risk of back injury when a cover is removed or reinserted. The new SMARTFLEX manhole cover is reliable, strong, lightweight, easy to handle, designed for noise reduction and resistant to corrosion, deformation and temperature inversion.

SMARTFLEX HDPE pre-assembled double wall tank sumps offer many advantages that only High-Density Polyethylene can provide. The containment chamber, along with the SMARTFLEX safe and reliable electrofusion welding process, provides guaranteed leak monitoring and the best secured system. These double wall sumps, pre-assembled with our double wall entry boots, use the electrofusion welding process which provides complete isolation of the sump chamber, whilst allowing the passage of the primary pipe and spigot fitting. This not only guarantees the reliability of the system and the constant monitoring, it also complies with current regulations and fully respects the environment. SMARTFLEX new double wall sumps are the most cost-effective choice, as they provide hassle-free installation, are simple to order and ready to set in place and connect. They all come with a liquid sensor at no extra charge and are pre-assembled with a ten-year labor warranty. Besides, when constantly monitored, triennial testing is not required.

The new model of SMARTFLEX double wall mechanical electrofusion entry boots have a monolithic structure for double wall coaxial fittings. This structure ensures its versatility and reliability even under the toughest field conditions. They have a robust design, HDPE coated wires embedded in fusion coils, improved shorter fusion timing and can be installed over wide temperature conditions.